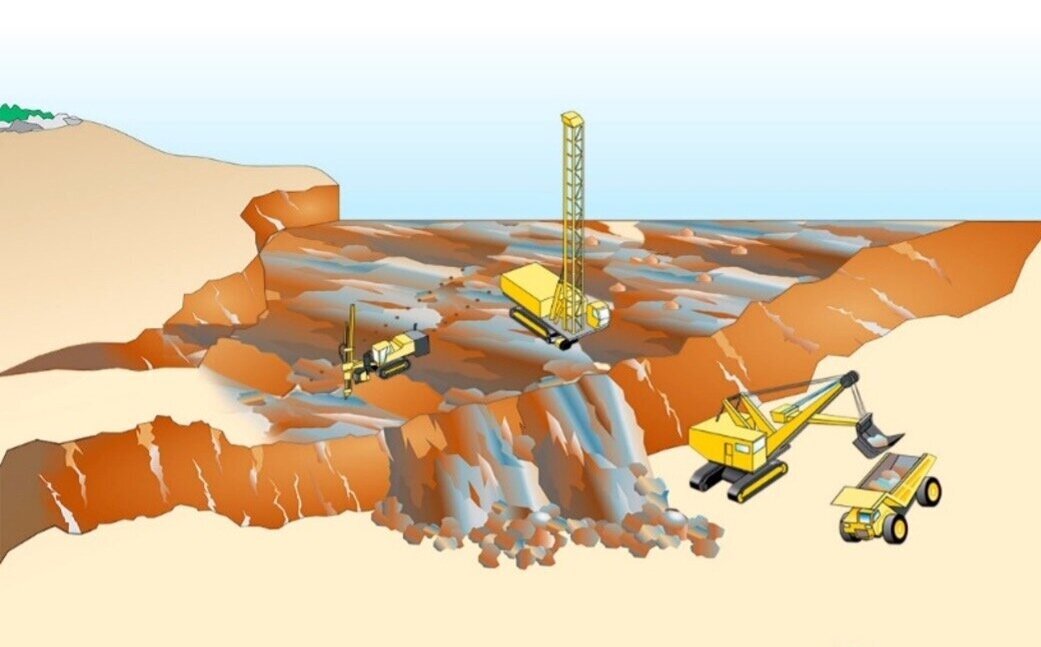

Autonomous Digital Mining Application - Blast Hole Sampling

This week, we continue our series of posts on the topic of Blast Hole Sampling and Analysis in Ore Grade Control in Mining and today we are talking about IMA Engineering’s Methods, Equipment and Results for Blast Hole Sampling. This article and the attached white paper are the continuation of our previous article that you can read here.

The Importance of Sampling and Analysis Accuracy in Grade Control

Blast hole sampling and analysis in Ore Grade Control in Mining is a topic that we feel, hasn’t been covered enough. During the month of March 2021, we aim to bring some clarity on this topic and to present some solutions to the current challenges faced by mining companies all over the world.

Sampling and Analysis - International Mining Magazine

IMA Engineering is one of the first companies to integrate X-ray Fluorescence (XRF) technology into the drill core analysis process. Together with our partners from Mine On-Line Service we developed and produced the Nordic region’s first mobile core scanner prototype more than seven years ago. Ilpo Auranen, Chairman of IMA Engineering, has been recently interviewed by the International Mining Magazine on the topic of drill core analysis.

On-line Sensors in Preconcentration

Waste rock removal in preconcentration has direct effect on energy consumption in crushing and grinding and chemicals in concentrator. In concentrator waste is separated and goes to tailings pond, however, preconcentration directly reduces the volume of the tailings. Download our paper from the 2020 Digital Pre-concentration Conference in Australia.

Integrated Mining Technologies for Sustainable Raw Material Supply

In 2017, the Iterams project consortium started the adventure towards more sustainable mining under the European Union’s Horizon 2020 program. The project marked a new direction to the mining industry in relation to mine water and tailings. One of the main challenges of this century is to conserve and protect freshwater. The team at ITERAMS has published THE H2020 ITERAMS INTEGRATED MINING TECHNOLOGIES FOR MORE SUSTAINABLE RAW MATERIAL SUPPLY book this month.

Ore Sorting Automation for Copper Mining with Advanced XRF Technology

Ore sorting is one of the focus areas mining companies are now looking at in improving mining proficiency and becoming ever more sustainable in mining. For almost a decade IMA Engineering has been developing sensor applications to better separate ore from the waste from early exploration to modern bulk ore sorting (or particle sorting).

The importance of Ore Sorting to the overall mining production

The Journal of Cleaner Production was recently published, as part of the EU-funded ITERAMS project. Ima Engineering is taking part in the EU-funded project ITERAMS, "Integrated Mineral Technologies for More Sustainable Raw Material Supply" and our CEO Jukka Raatikainen contributed to this article which is a review of closed water loops with ore sorting and tailings valorization for a more sustainable mining industry.

IMA Engineering joins “illuMINEation” EU-Project

We are proud to announce that IMA Engineering is a partner in the new EU-Project “illuMINEation”. Ready to kick-start in September, the project’s aim is to embed digital thinking into the heart of the mining industry, improving the digital skills of the personnel in the mining business and by enhancing cooperation.

Remote support to tackle Covid-19 restrictions - Mining Finland Interview

Our CEO, Mr. Jukka Raatikainen was recently interviewed by Mining Finland on how IMA Engineering approached the recent COVID-19 epidemic.

The Covid-19 epidemic has pushed mining technology companies to develop new ways of delivering and maintaining their products.

New IMACON 100 version deliveries started

Our latest IMACON slurry-analyzer version is based on same proven XRF technology that made the IMA Engineering on-line sensors well-known in the mining industry around the globe.

Increase mine efficiency and productivity with the IMA BOSS

Mining companies are faced now with the challenges to meet their targets for this and coming years. IMA Engineering suggests that mines increase the mill head grade by processing higher grade ore. However, this can lead to a challenge, without the low grade ore going to waste rock area.

Ore sorting - more than profit

We are extremely proud that Ilpo Auranen, Chairman of IMA Engineering has been interviewed by International Mining Magazine. Read more and download the whole interview.

Welcoming the Chinese Western Mining Delegation

This week the Western Mining Group from China is visiting Finland and meeting representatives from the major mining companies in the country.

IMA and TecProMin at Perumin 34

Last month we were in Peru for Perumin 34, the second-largest mining convention in the world and we were happy to meet customers and so many old and new friends.

The Kitwe Seminar for Small Scale Miners

In June IMA Engineering continued the collaboration with the Zambian mining technology through the Kitwe seminar. IMA Engineering has been appointed by the Finnish Embassy and AGS Programme Management Unit in Lusaka to conduct a feasibility study whose aim is to develop new mining businesses and encourage collaboration between Finnish and Zambian mining technology providers.

IMA Engineering in the Africa Outlook magazine

We are pleased to announced the new issue of the Africa Outlook magazine where IMA Engineering was featured. Africa Outlook is a digital and print product for business executives across a wide range of industries wanting to keep up with the latest in global news affecting African businesses.

IMA Engineering in the International Mining publication

The publication is read by professionals in the mining industry around the world who are interested in the latest innovations and solutions that help lowering costs, increase performance, enhance safety and maximise production.

IMA at The Mining Technology Partners Podcast

We are happy to share with you this episode of the Mining Technology Parnters Podcast where Ilpo Auranen, Chairman of IMA Engineering and CEO of Mine On-Line Service was invited to talk to Cynthia Collins.

Blast holes analyzed on-line in real time!

The new technologically proofed method was financed by EIT Raw Materials. A new method to get representative samples and accurate analysis of the bench. Faster and representative analysis of cones!

IMA delivery to Zambia

IMA started 2019 on a high note. We are happy to share with you some news about our international growth.