Sustainable Mining Practices - Integrating Sustainability with Smart Technology

Sustainable Mining Practices - Integrating Sustainability with Smart Technology

IMA Engineering received the Kauppalehti Achiever Certificate 2022

IMA Engineering received the Achiever certificate 2022 from Kauppalehti, with a score of 82 out of 100 points. This places IMA in the first 2% of Finnish companies, according to its financial performance.

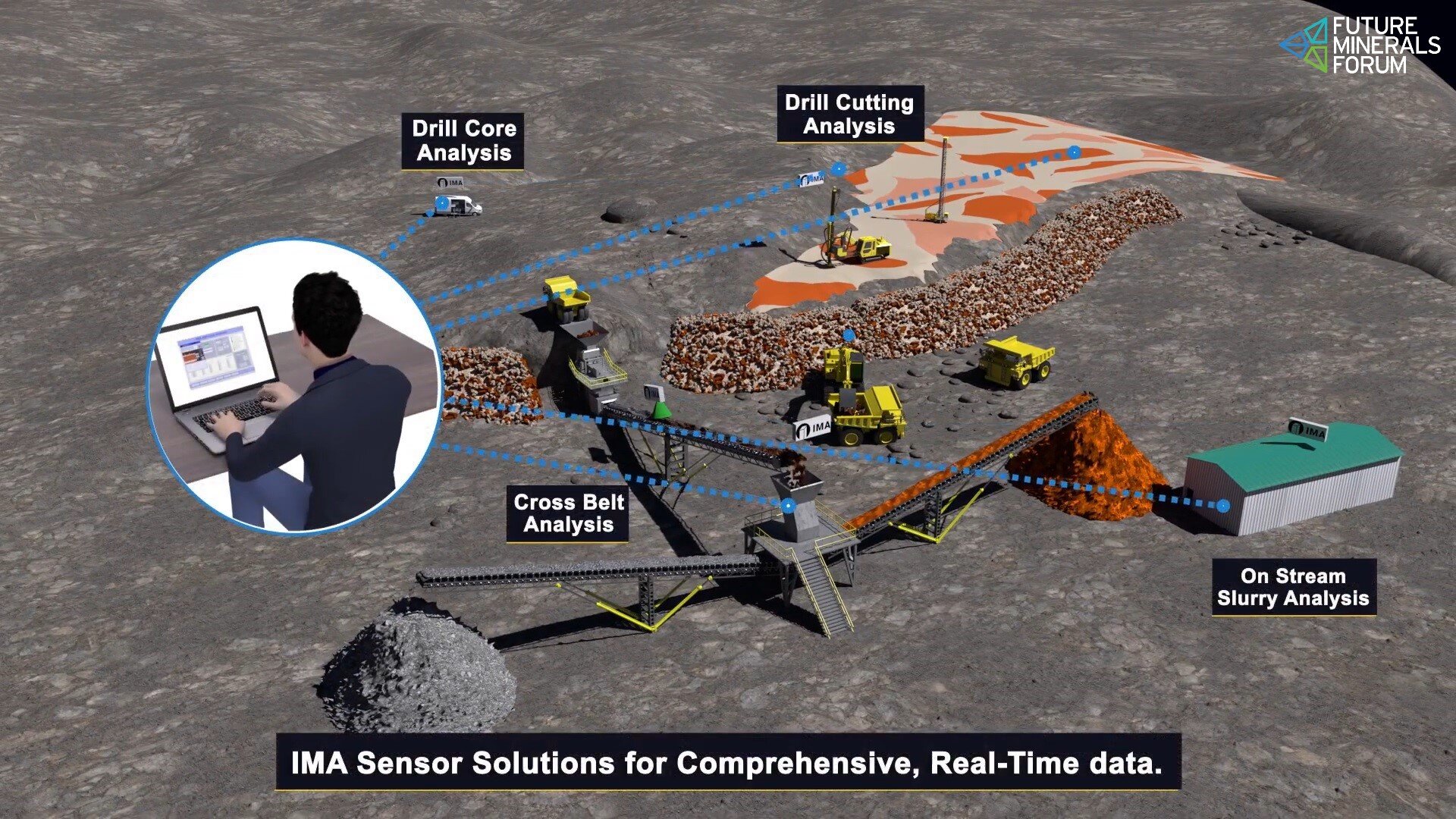

IMA Engineering at The Future Minerals Forum, in Riyadh

IMA Engineering will be attending the Future Minerals Forum, in Riyadh, Saudi Arabia (10-12 January 2023).

IMA is the only mining technology company on the 2022 Deloitte Technology Fast 50 list

MA Engineering has been chosen as the only Finnish mining technology company on the 2022 Deloitte Technology Fast 50 list.

IMA Engineering will attend The Mining Show, in Dubai

MA Engineering will attend The Mining Show, at the Festival Arena in Dubai. Jukka Raatikainen, the company’s CEO is going to participate on the 15th and 16th of November, together with its partner, Excel Industries.

IMA Engineering’s solutions arouse interest at Zimec 2022

IMA Engineering presented its bulk ore sorting smart solution, at Zimec 2022, the longest-running mining and energy event in Zambia. The event in Kitwe is taking place between 1-3 November and brings together important mining players and technology providers.

One step closer to waterless operations from mine to mill

IMA Smart Mining Solutions was recently invited to contribute to an article on sampling and analysis solutions for Science Direct.

IMA Engineering, “a huge step forward in my career”

Upon completing the 1st academic year of my master’s studies, I joined IMA Engineering Oy as a Research Engineer. This was for my summer internship and I have been working full-time since early May this year.

IlluMINEation: IMA Autosampler, ready for the RHI Magnesita mine

IMA representatives discussed on-site the future proceeding with installing the IMA Autosampler in RHI Magnesita underground mine. The visit and the installation are part of the EU-funded Horizon 2020project illuMINEation.

The benefits of ore sorting and sensing in mining

Ilpo Auranen, Chairman of IMA, has been recently interviewed by the International Mining Magazine on the topic of ore sorting. In this interview, Ilpo talks about the benefits of ore sorting and sensing in the mining industry, sharing a success story from an iron mine in Brazil.

IMA Engineering - a successful example of the Finland Innovation

IMA Engineering will be present in “The Key to Success of the Finland Innovation Ecosystem” webinar cooperation with Chilean companies. After Nicolaides, IMA’s partner in Chile, set up and run a successful IMA FCA pilot for the largest iron producer in the South American country, IMA also becomes a successful example for the Finnish innovation ecosystem.

IMA Fast Conveyor Analyzer pilot in iron mine in Chile

2022 has started on a high note with great news from our partners and customers in South America. Our local partner in Chile, Nicolaides has done an amazing job in setting up and running a successful IMA FCA pilot with Compañía Minera del Pacífico (CMP), the largest iron producer in Chile.

IMA Smart Mining Solutions in 2021

There is no doubt that 2021 was an interesting year for everybody. During this month we take some time to count our achievements and learn how we can further improve and serve the world. We also produced and launched our solutions video this year, to better illustrate how IMA Smart Mining Solutions work together to improve mining efficiency and reduce mining costs. For more IMA Smart Mining Solutions please visit our YouTube Channel.

Reducing carbon footprint in mining by bulk ore sorting

Sustainability and environmental consideration stand at the core of IMA’s philosophy. Everything we do is to help mines become more efficient and environmentally sustainable. In Bulk Ore Sorting the IMA BOSS is removing waste rock from mineral concentrator feed material and replacing it from ore recovered by sorting from waste rock.

Remote installations and reduction in CO2 emissions

With the ongoing COVID-19 crisis, we have reduced and, in many cases, halted completely our travel plans to visit our customers. We worked hard to transform and adapt to the new global economical and environmental situations, and this led to remote deliveries and installation of our smart mining solutions. This month we delivered and installed the IMACON remotely in Peru. Our solutions are installed and used in a copper mine.

Sampling and Analysis Solutions for Mine Grade Control

IMA Smart Mining Solutions was recently invited to write an article on sampling and analysis solutions for Africa Mining Insight. The article discusses and highlights the benefits the IMA Smart Mining Solutions core products have for the mining industry.

The Autosampler used globally in different mining applications.

Earlier this year we introduced The Autosampler - A new IMA product for drill chip sampling and now we have a few exciting updates regarding product deliveries and demand. You can read more about the IMA Autosampler, its features and benefits here.

Autonomous Sampling and Analysis Solutions

Mr. Ilpo Auranen, Chairman of IMA Engineering has been recently interviewed by Dan Gleeson from the International Mining Magazine on the topic of Autonomous Sampling and Analysis Solutions. You can read the article featuring Mr. Auranen’s interview in the 2021 May issue of the International Mining Magazine. Read the interview online or download a copy.

Delivering Smart Mining Solutions to Remote Locations

Since the beginning of 2021, we have seen an increase in demand for our data driven mining technology, especially for IMACON and conveyor belt applications (BOSS – Bulk Ore Sorting System). This month we are delivering and remotely installing IMACON and conveyor applications solutions in Peru, Chile and South Africa.

Digital and Sustainable Ore Sorting Solutions

Mr. Ilpo Auranen, Chairman of IMA Engineering has been recently interviewed by Dan Gleeson from the International Mining Magazine on the topic of Ore Sorting and Pre-Concentration Technology. You can read the whole article featuring Mr. Auranen’s interview in the 2021 March issue of the International Mining Magazine. Read the complete article and interview online or download a copy below.